Natural Wood Veneer Block Board

first grade core

high quality control

hundreds of color for choice

Product Name |

Melamine veneer Block board/blockboard |

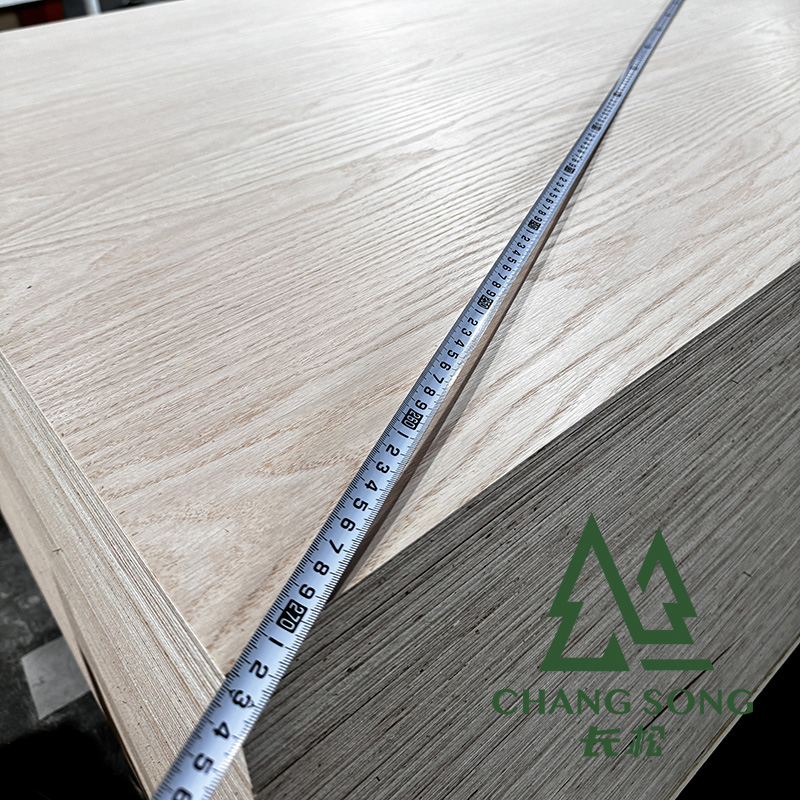

Size |

1220x2440mm, 1250x2500mm, 1500x3000mm or as clients requirement |

Thickness |

15mm, 16mm, 17mm, 18mm, 19mm, 20mm, 22mm, 25mm, ect |

Face/Back |

Solid Color (Green, Yellow, Coffee, Black, Titanium White,Warm White, Red, etc),Wood Grain (Cherry, Beech, Wenge, Walnut)and others melamine paper. |

Surface Treatment |

Sanded, UV coated, smoked or embossed |

Veneer Cut Type |

Q/C, C/C or R/C |

Core |

Malacca, paulownia, fir, poplar, lauan,radiation pine,pinus sylvestris , ect. |

Glu |

E0, E1, E2 |

Grade |

A, AA ,AAA |

Joint way |

Overlap joint, end joint, scraf joint, finger joint |

Strength |

High bending strength Strong nail holding |

Density |

450~680kg/m3 |

BWR – Phenol formaldehyde synthetic is used for glueing the plies together. This is a synthetic plastic resin.MR – Urea formaldehyde resin is used for bonding the plies to each other. UF resin is not considered to be very eco-friendly.

Some shopkeepers erroneously (or is it deliberately?) inform customers that Marine plywood is the same as BWR grade waterproof plywood. This is simply not the case. Marine plywood is a much better kind of plywood in which unextended (undiluted) phenolic resins are used for glueing the plies together, which makes it stronger. Marine ply is meant for extreme cases of exterior use, such as for making boats and ships or other river equipment, where the plywood is sure to become and remain wet for a prolonged duration.

1. **Raw Material Inspection**

- Check if the quality of raw materials provided by suppliers meets company standards and specifications.

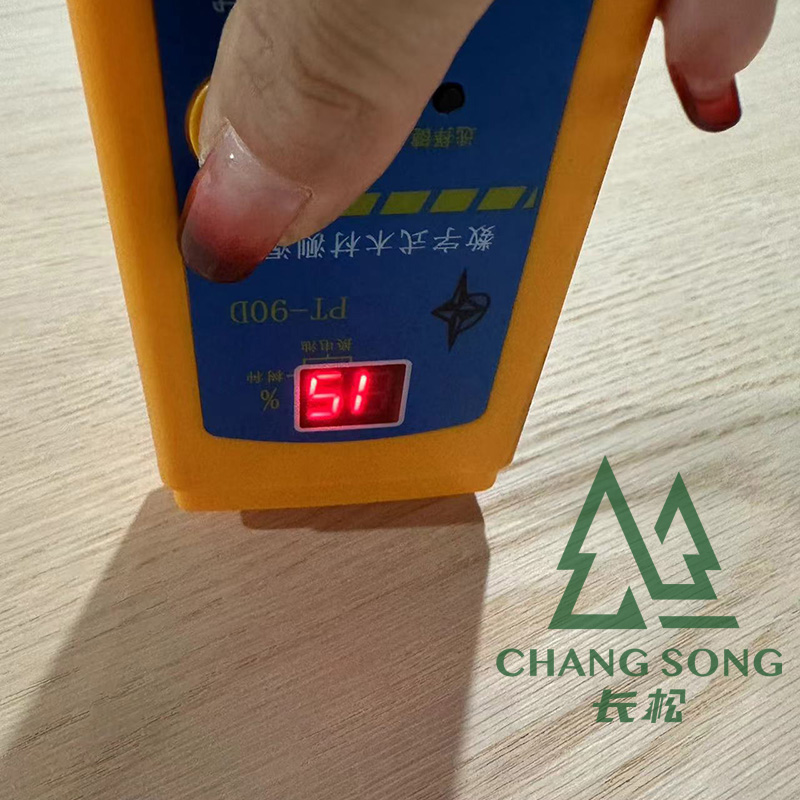

2. **Pre-Production Sample Testing**

- Before production begins, sample testing is conducted to ensure the sample meets production and customer standards.

3. **In-Process Quality Control**

- Conduct periodic inspections during production to monitor whether production equipment, processes, and operators comply with standard operating procedures.

4. **Semi-Finished Product Inspection**

- Perform sample checks on semi-finished products during the production process to ensure subsequent processes are not affected.

5. **Finished Product Quality Inspection**

- After production is completed, conduct a full or random inspection of finished products to verify if dimensions, appearance, and functions meet the order requirements.

6. **Pre-Packaging Inspection**

- Check the quality of packaging materials and verify product labels, quantities, and packaging methods are correct.

7. **Final Inspection and Report**

- Conduct random re-inspection and issue the final quality inspection report, recording all inspection data.

8. **Customer Acceptance**

- If required, the customer can participate in the final acceptance to ensure the product meets their requirements.

9. **Corrective Actions**

- If any quality issues are found, corrective actions are implemented to prevent recurrence.

Shouguang Changsong Wood Industry Co.,Ltd is located in Shouguang city,Shandong Province ,China,where is famous for plywood industry .

Our mill was estabilished in the year of 2002 , and has developed production lines widely,including film faced plywood,commercial plywood,fancy veneered board,melamine MDF,block board ,and door skin etc.

We insist on quality first , performing quality inspection in every process of production to make sure each pc of plywood is satisfied by client. We care what clients care,and we gain trust from clients all over the world.

We pursue human health, natural life all the time in line with the management theory of honest and sincerity! We do welcome every old and new friend, domestic and international traders to send enquiries or letters, negotiate the business and seek development together.