MDF Acoustic Panel

Request QuoteMDF Acoustic Panels are our innovative products created specifically for customers who pursue superior acoustic performance and refined design. By using high-quality materials and advanced craftsmanship, we provide you with superior acoustic solutions that create tranquility and comfort in your space.

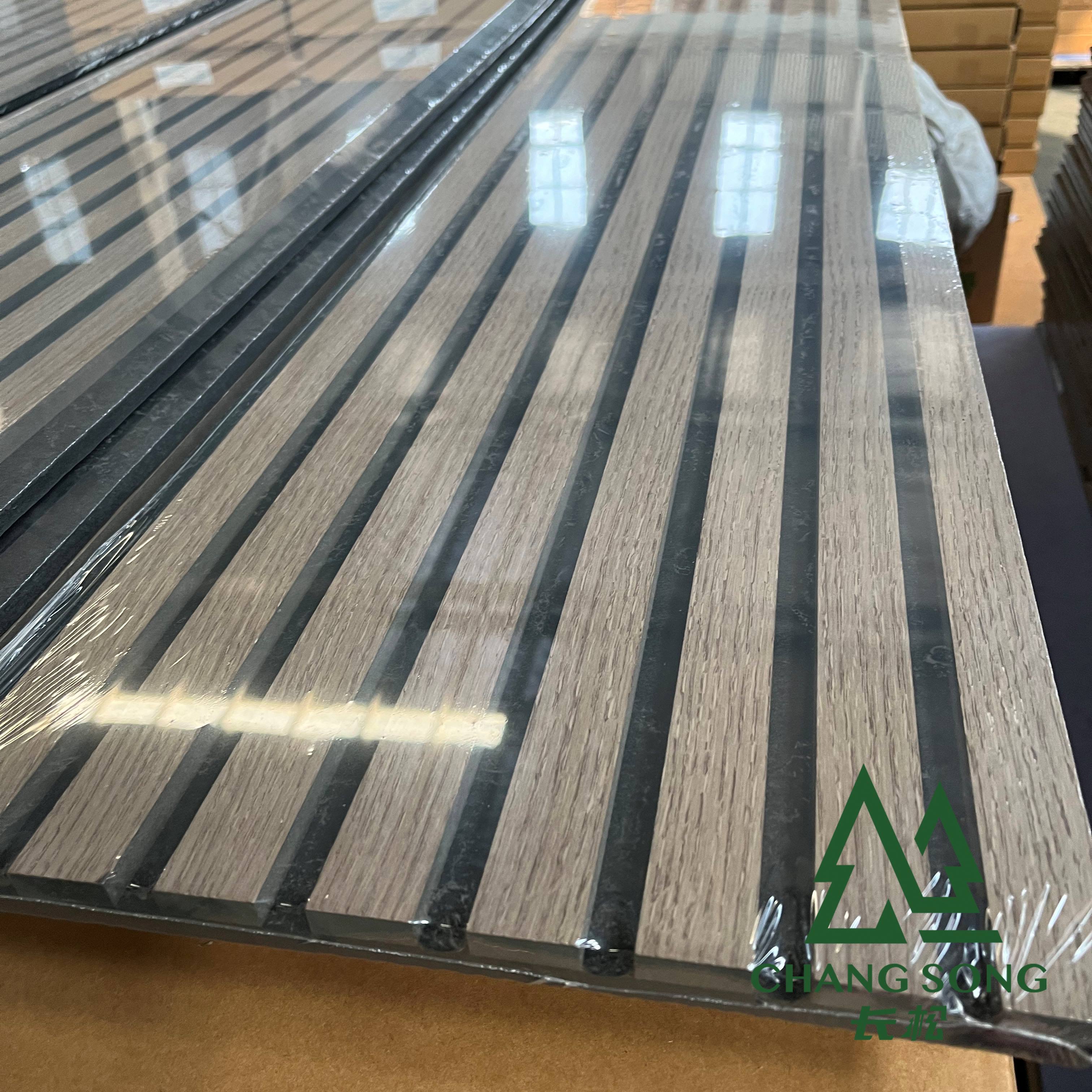

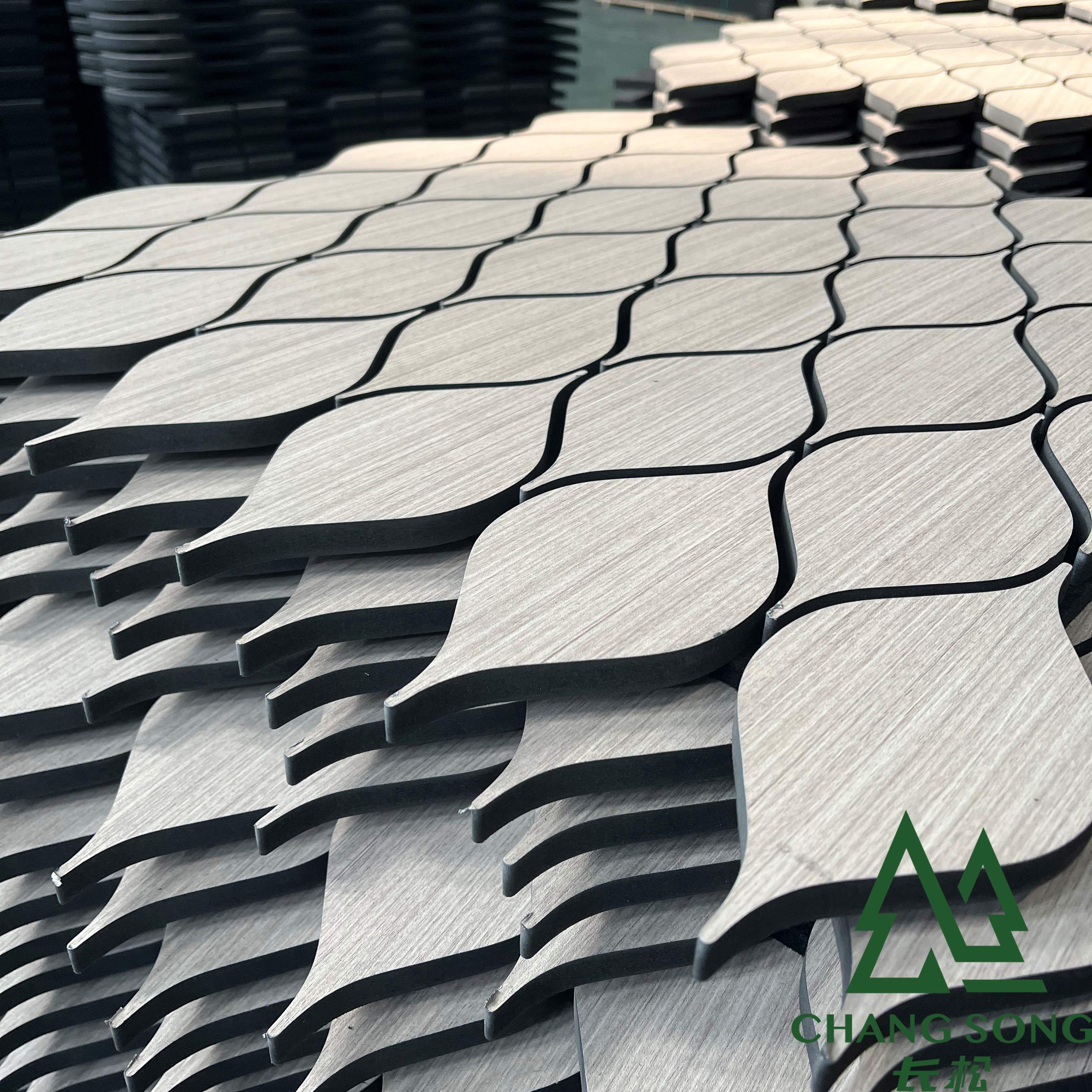

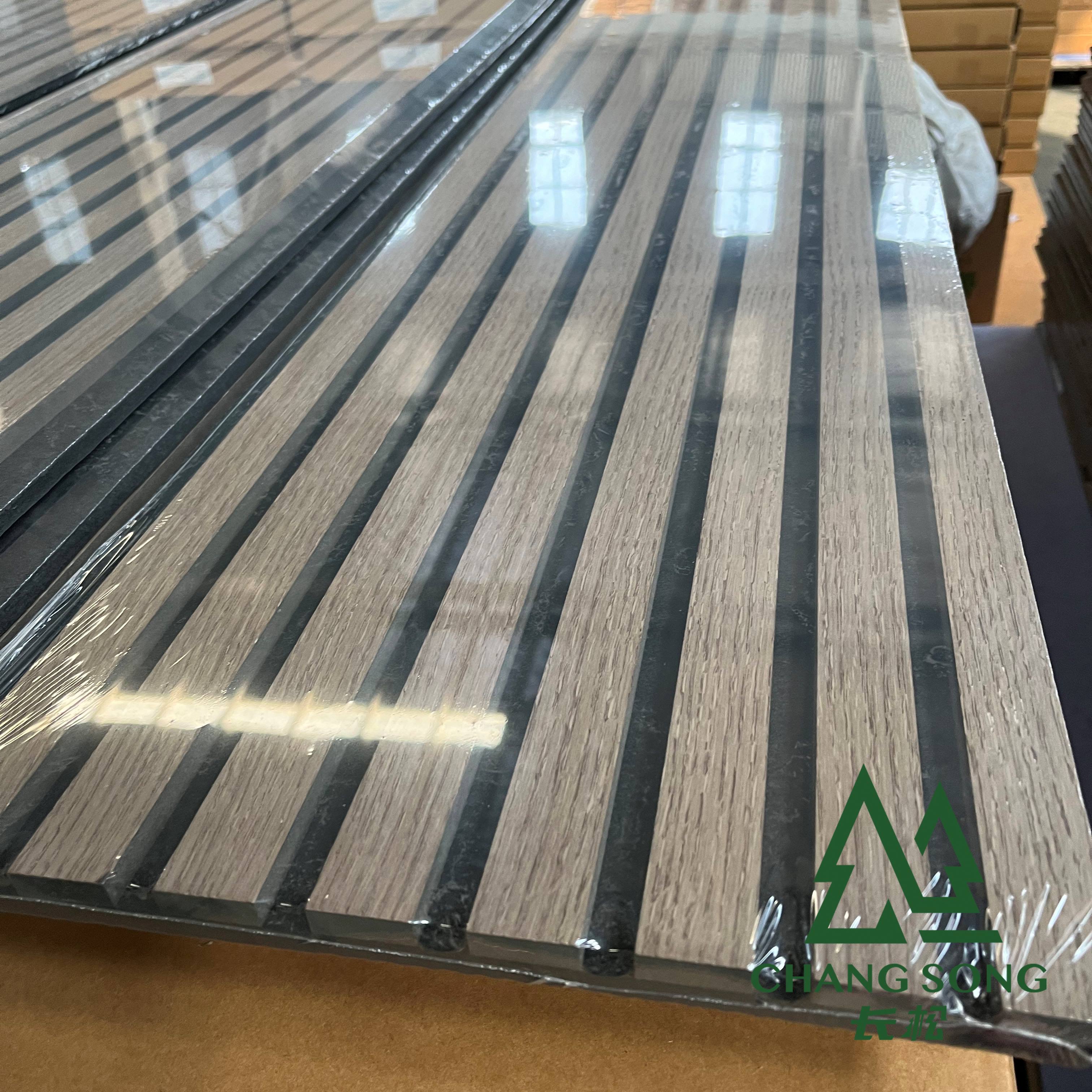

1. Unique design and texture:

Our design team focuses on innovation and injects unique designs and textures into MDF acoustic panels, making them not only acoustic materials but also decorations for the space.

2. Environmental protection and health:

We are committed to using environmentally friendly materials to ensure that MDF acoustic panels meet environmental standards to protect your air quality and living environment.

3. Easy to install:

MDF acoustic panels are designed to be easy to install without cumbersome construction procedures and can be applied directly to walls and ceilings, making your decoration process easier.

4. Tight structure and strong durability:

The high density and strong structure of the MDF material guarantee the stability and durability of the acoustic panels, making them ideal for long-term use.

5. Acoustic optimization:

Through professional acoustic optimization design, our MDF acoustic panels perform excellently in sound absorption and insulation, providing a clear and quiet acoustic environment for your space.

We can customize sizes, offers versatile options to suit different project requirements. Its material composition ensures it is free from formaldehyde, promoting a healthier environment. The installation process is convenient, offering the choice of screws or mounting glue.

Backed by a 1-year warranty, also provides project solution capabilities, including 3D model design, making it an all-encompassing choice for interior design projects. Certified with CE, REACH, and FSC, it guarantees a high standard of quality and environmental responsibility.

1. **Raw Material Inspection**

- Check if the quality of raw materials provided by suppliers meets company standards and specifications.

2. **Pre-Production Sample Testing**

- Before production begins, sample testing is conducted to ensure the sample meets production and customer standards.

3. **In-Process Quality Control**

- Conduct periodic inspections during production to monitor whether production equipment, processes, and operators comply with standard operating procedures.

4. **Semi-Finished Product Inspection**

- Perform sample checks on semi-finished products during the production process to ensure subsequent processes are not affected.

5. **Finished Product Quality Inspection**

- After production is completed, conduct a full or random inspection of finished products to verify if dimensions, appearance, and functions meet the order requirements.

6. **Pre-Packaging Inspection**

- Check the quality of packaging materials and verify product labels, quantities, and packaging methods are correct.

7. **Final Inspection and Report**

- Conduct random re-inspection and issue the final quality inspection report, recording all inspection data.

8. **Customer Acceptance**

- If required, the customer can participate in the final acceptance to ensure the product meets their requirements.

9. **Corrective Actions**

- If any quality issues are found, corrective actions are implemented to prevent recurrence.